PROTECT system packaging made of Styropor® Ccycled™

We are taking another important step on the road to more sustainability: The proportion of Styropor® from chemical recycling in our PROTECT- system packaging portfolio is going to increase significantly in the first quarter of 2021. To make this happen, we are collaborating with BASF, whose Verbund site is virtually only a stone’s throw away from the eutecma headquarters in the Mannheim harbor.

We are taking another important step on the road to more sustainability: The proportion of Styropor® from chemical recycling in our PROTECT- system packaging portfolio is going to increase significantly in the first quarter of 2021. To make this happen, we are collaborating with BASF, whose Verbund site is virtually only a stone’s throw away from the eutecma headquarters in the Mannheim harbor.

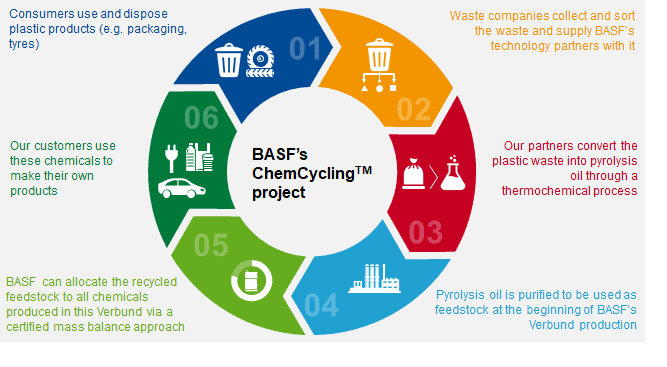

The magic word is ”Styropor® Ccycled™” and is a secondary feedstock made of pyrolysis oil, which is made from plastic waste in the chemical recycling process, converted for the chemical industry and allocated via a certified mass balance approach within the BASF Verbund system.

PROTECT- system packaging Ambient / Cool / Frozen with Styropor® Ccycled™ go into series production

We are going to start this project with a selection of PROTECT system packaging solutions that use Styropor® Ccycled™as feedstock. Our customers can still choose between pharmaceutical packaging made of conventional Styropor® or Styropor® from chemical recycling.

Even though both materials possess the same properties and are of identically high quality, Styropor® Ccycled™has a better CO2 footprint. And so, the most important message to pharmaceutical manufacturers and suppliers is: The quality remains the same, a re-qualification of PROTECT system packaging with Styropor® Ccycled™is NOT NECESSARY.

So for pharmaceuticals customers who place a premium on sustainability in their supply chain and who want to communicate that point in their communication with stakeholders, the following still holds true: eutecma is the optimal partner by your side.